EVER WONDER IF YOUR WAREHOUSING facility’s (or facilities’) performance is aligned to your corporate strategy? That is, does the work tackled daily by your warehouse associates support your organizational mission, vision, values and long-term goals?

To help warehousing managers — and their C-level bosses — get a more accurate answer, the Warehousing Education and Research Council (WERC) has produced an annual benchmarking study of key warehousing and distribution performance metrics for the last 13 years. The resulting report, “DC Measures,” is released each spring.

To help warehousing managers — and their C-level bosses — get a more accurate answer, the Warehousing Education and Research Council (WERC) has produced an annual benchmarking study of key warehousing and distribution performance metrics for the last 13 years. The resulting report, “DC Measures,” is released each spring.

The report shows operations professionals, including directors, managers and supervisors how their facility’s performance compares to others in the field. The study captures 50 key operational metrics grouped into seven categories: customer, operational, financial, capacity/quality, employee/safety, perfect order and cash-to-cash cycles.

The research is conducted by Georgia College & State University’s Karl Manrodt, PhD, professor of logistics and director of the master of logistics and supply chain management online program and Donnie Williams, PhD, assistant professor of logistics/supply chain management, as well as TSquared Logistics’ Founder Joseph Tillman. Conducted in January 2016, the survey asked more than 300 respondents to share their actual performance levels from 2015.

As with previous reports, the research team found that top-level bosses are very interested in performance measurements. This year, more than 35 percent of respondents said they report to the C-suite, a three percent increase from last year.

That fact ties in to one of the most interesting findings in this year’s report; according to Manrodt, 60 percent of respondents say their top-level bosses most often seek the “distribution costs as a percent of the cost of goods sold (COGS)” metric. In Tillman’s opinion, the finding shows C-level and senior managers are using that metric as a primary indicator of whether or not warehousing and distribution performance aligns with overall organizational strategic goals.

As a follow-up to that question, the research team asked what other measurements senior managers investigate if they see signs of declining performance. It turns out they look at the financial measures of lost sales due to stock outs and inventory turns.

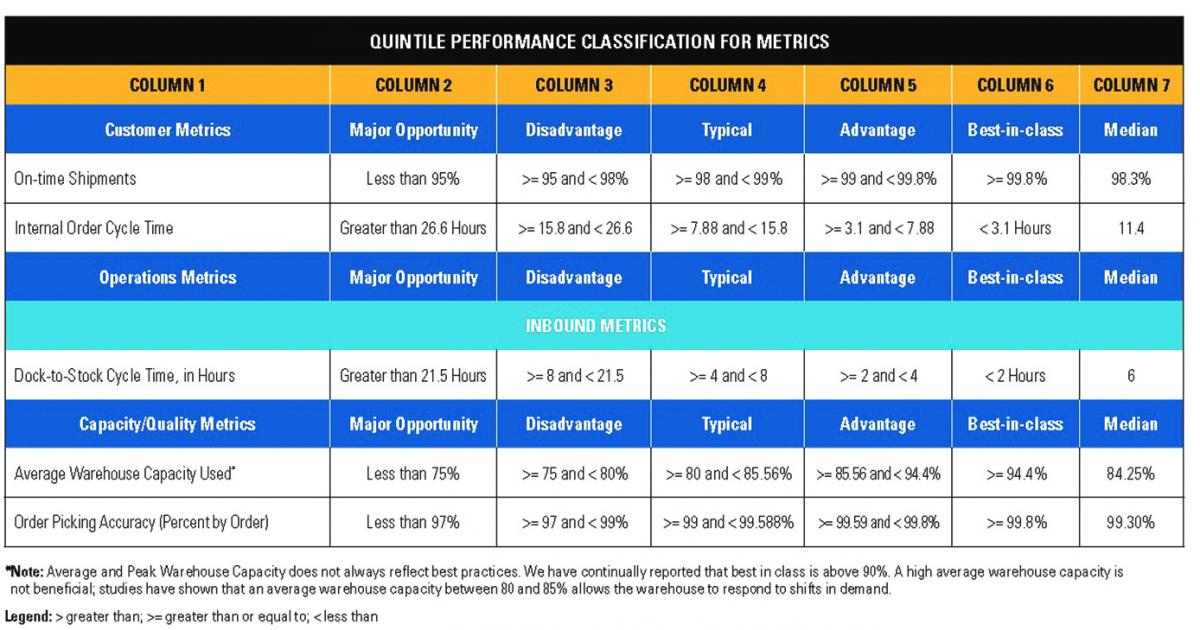

That said, however, the five most popular metrics tracked by respondents are:

-

On-time shipments

-

Internal order cycle time (in hours)

-

Dock-to-stock cycle time (in hours)

-

Average warehouse capacity used

-

Order picking accuracy (percent by order).

As with the 12 previous iterations of the report, the gathered benchmarking data is reported using a “quintile” format, which evaluates the data on a five-point maturity scale. This structuring methodology reflects where respondents are situated with respect toward having achieved a “best practice” within a given metric. To be considered “best-in-class,” performance levels must fall within the top 20 percent of all respondents.

Using the Metrics

So what do the “DC Measures” findings mean to your operation? Probably not much if you haven’t been measuring your own key operational metrics.

That’s why, for the past decade, WERC has published the Warehousing and Fulfillment Process Benchmark & Best Practices Guide (WERC just released an updated edition). The Best Practices Guide breaks out the key operational metrics researched in the “DC Measures” report, parsing them into eight separate chapters. Each chapter covers one of the eight primary functional areas within the four walls of a warehouse and a total of 117 processes/attributes:

-

Receiving & inspection

-

Material handling & putaway

-

Slotting

-

Storage & inventory control

-

Picking & packing

-

Load consolidation & shipping

-

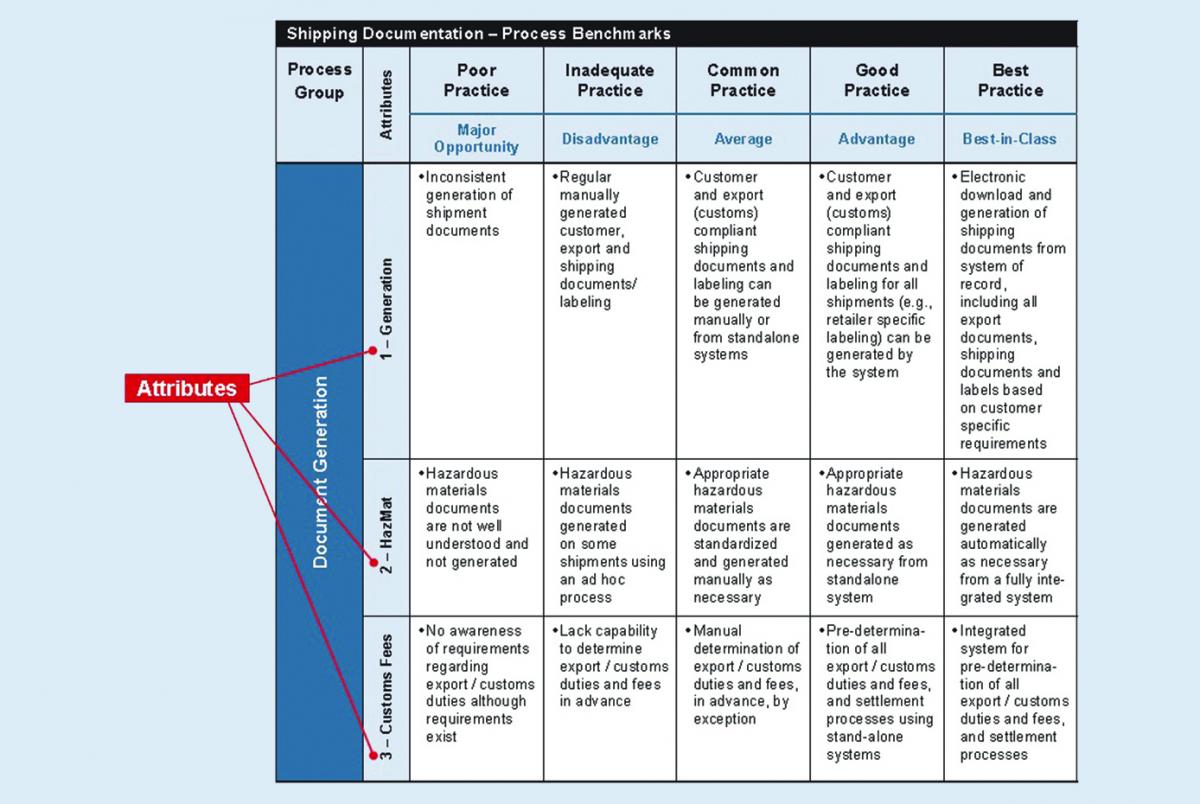

Shipment documentation

-

Warehouse management system (WMS).

In addition to overviewing the best practices within a given functional area, the Best Practices Guide acts as a workbook of sorts, encouraging readers to evaluate their own operations against five sample process benchmarks (poor practice, inadequate practice, common practice, good practice and best practice). It also includes a self-assessment exercise with corresponding rankings and an area for performing a quantitative benchmarking of a facility’s performance against the industry averages published in the most recent “DC Measures” study.

Among the Best Practices Guide’s authors is Steve Murray, principal consultant and chief researcher at Supply Chain Visions. Murray also serves as lead auditor for WERC’s Warehouse Assessment and Certification Program, having conducted more than 60 warehouse audits over the past few years. He reports that some of the facilities he’s audited rely heavily on the Best Practices Guide for process development throughout their operations, while others use it more selectively.

Murray recommends that companies working through the Best Practices Guide focus on the metrics that have the most value to their operation in terms of supporting the organization’s mission, vision, values and long-term goals. For example, if a company plans to invest in any process improvement program — either changing how work is done or implementing new hardware or software — the only way to ensure maximum return on investment is through measurements.

For companies that need a more objective perspective on their warehouse’s performance, Murray can, of course, conduct a WERC Warehouse Assessment and Certification. The audit grades each functional area based on the Best Practices Guide’s recommendations, and offers insights into potential improvements that will enhance their metrics.

Put the “DC Measures” Report

In addition to the Warehousing and Fulfillment Process Benchmark & Best Practices Guide and the Warehouse Assessment and Certification audits, WERC can help companies better understand the operational metrics they should be focusing on to achieve their business strategy goals. WERC offers customized comparative reports that compare a company’s data against “DC Measures” findings, including medians and quintile rankings specific to industry, customer type and company size.

Additionally, several metrics identified in the study have been embedded into business intelligence tools offered from software provider TECSYS. Users of the Visual Metrics executive dashboard tool can easily see where their operational key performance indicators (KPIs) align to those of competitors as benchmarked by WERC’s industry study.

About WERC

Warehousing Education and Research Council (WERC) is the only professional association focused exclusively on warehouse management and its role in the supply chain. Members are experts from all facets of the distribution industry who come together to share practical knowledge and professional expertise to improve individual and industry performance