In Michigan, the Michigan Economic Development Corporation (MEDC) works behind the scenes to help generate private investments, create jobs and make key industry connections. It provides the necessary tools for growth, including within the manufacturing realm. The state emphasizes that a strong, healthy business climate includes a sensible business-tax structure, fiscal stability, regulatory reforms and support for private-sector development projects that are vital to improving economic well-being. This includes programs like Pure Michigan Business Connect (PMBC), which helps facilitate connections between local and global suppliers and purchasers through matchmaking summits, generating more than $8 billion in new contracts to date.

As a key entry point to the North American market, Michigan is a natural fit for advanced manufacturing facilities. It is home to 18 commercial airports and numerous international crossings with Canada, offering various channels for businesses to move goods throughout the state, country and world. To date, the MEDC has helped 789 companies increase their export sales by $2.34 billion to 153 countries, with Mexico, Canada and China being among the top-reported export markets.

More than 100 years ago, Michigan put the world on wheels. Today, the automotive industry is shifting as companies move toward advanced manufacturing to develop the mobility solutions of the future.

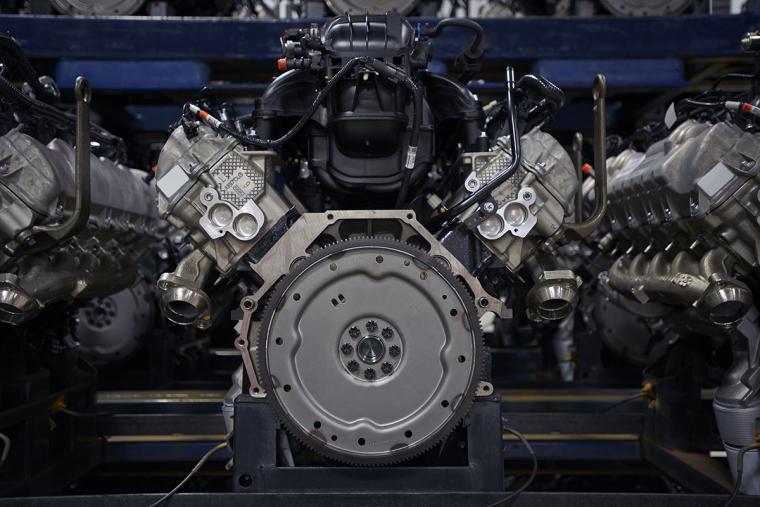

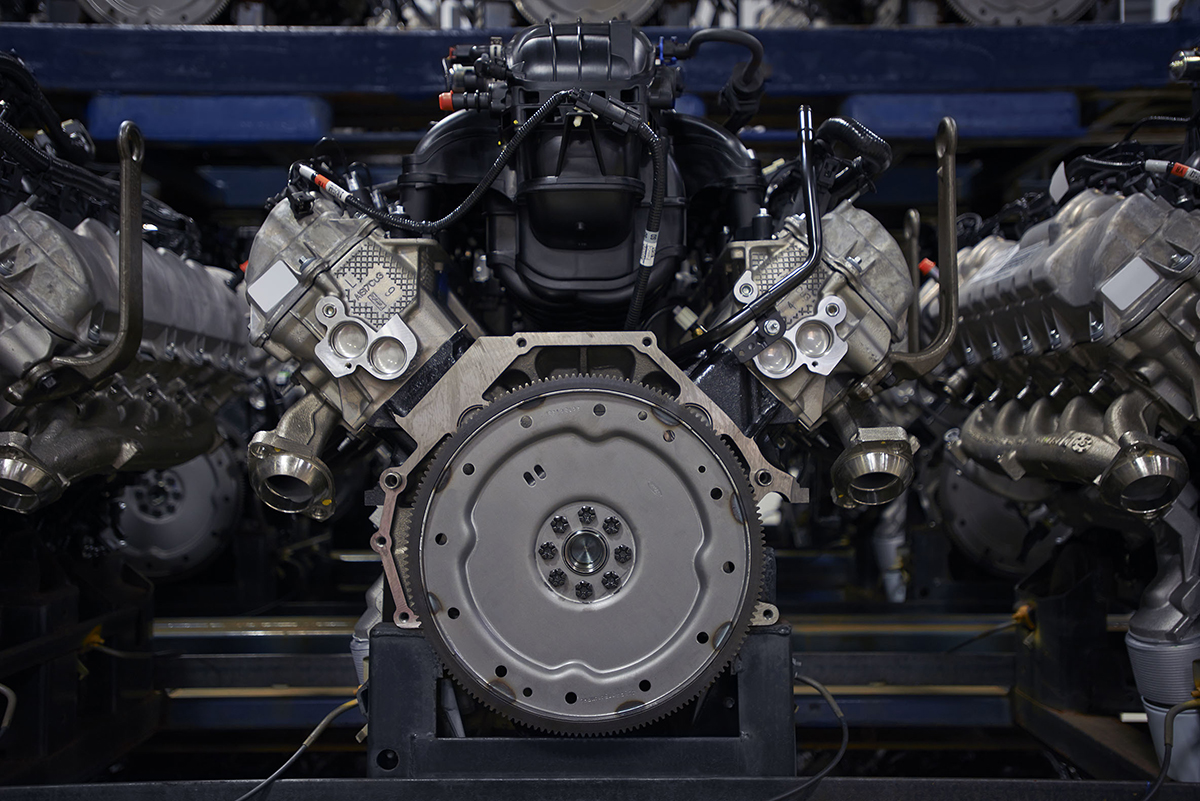

Take, for example, Fiat Chrysler Automobiles (FCA). The company is investing $4.5 billion and creating 6,433 jobs to build a new automotive assembly plant in Detroit and add to its production at five existing Michigan facilities, with the ability to build fully battery-electric models in the future. This is monumental for FCA and Detroit, as it is the single largest investment the company has made in U.S. operations since the recession, and the first new automotive assembly plant built in Detroit in nearly 30 years. FCA’s investment and its emphasis on electrification capabilities is a signal that Michigan remains a leader in future transportation solutions.

General Motors is also investing in testing the future of mobility at its Kettering University GM Mobility Research Center, serving as a proving ground and outdoor research facility for developing new mobility systems. The facility in Flint is the only one of its kind on a college campus in the country, keeping Michigan at the forefront of autonomous vehicle research and development.

Meanwhile, Ford is investing in the historical Michigan Central Station, where the company and its partners will develop autonomous and electric vehicles and design mobility services and solutions for urban environments. The company is also expanding its battery electric vehicle (BEV) manufacturing footprint at its southeast Michigan plant, which will become the production home for the company’s next-generation BEV flexible architecture models. Additionally, Ford is investing $500 million in Rivian, an electric car startup based in Plymouth to accelerate the company’s efforts to field a range of electric cars and trucks, while streamlining operations, cutting costs and increasing profitability.

Even the self-driving company Waymo from Silicon Valley is establishing a high-tech manufacturing facility in Detroit’s American Axle & Manufacturing plant, allowing it to integrate its self-driving systems into the vehicle platforms of its OEM partners.

These expansions and investments work to further solidify Michigan’s role in manufacturing and deploying the vehicles—and technology—of the future. However, Michigan’s manufacturing expertise also extends beyond advanced automotive manufacturing.

Thanks to companies like Lightweight Innovations for Tomorrow (LIFT) and the Institute for Advanced Composites Manufacturing Innovation (IACMI), Michigan is helping lead the development in transformative lightweight materials that can be used in the aerospace, automotive and defense industries to create cost-savings and fuel efficiency.

And with medical device manufacturing companies like Stryker on the west side of the state and Able Medical Devices in the Upper Peninsula expanding their manufacturing footprints throughout Michigan, the state is on its way to making a name for itself as a key competitor in the medical manufacturing realm.

The transformation in manufacturing even creates opportunities for Michigan farmers to adapt the way they produce and distribute their products while maximizing their profits and economic impact in the state. Silicon Valley-based startup FarmWise is collaborating with legacy automaker Roush to manufacture autonomous farming robots in Michigan, merging the future of agriculture, technology and business from within the state.

Advanced manufacturing even rolls into daily life, with Steelcase and Haworth, makers of office, hospital and classroom furniture, helping build a world-class furniture manufacturing hub on the west side of Michigan.

A Workforce Merging Digital and Physical Technologies

At the end of the day, though, there is no denying that the increased use of automation in manufacturing will impact the future workforce as Industry 4.0 merges digital and physical technologies in the workplace.

In Michigan, businesses are embracing this “Fourth Industrial Revolution,” recognizing that the workplaces of the future will rely on human-machine interaction to produce successful outcomes. By proactively preparing Michigan’s workforce through programs like MI Reconnect—creating a tuition-free pathway for workers to upskill and receive in-demand industry certificates—and organizations like Automation Alley offering training tools and resources, Michigan is providing its businesses the support they need to grow in the digital age.

By leveraging Michigan’s strong manufacturing heritage, premier location, robust business climate and commitment to training, retaining and attracting top talent, the state is well-positioned to lead the manufacturing industry of today into the advanced manufacturing of the future. T&ID

Incentives-at-a-Glance

• Michigan’s individual income tax rate is one of the lowest in the nation at a flat 4.25 percent.

• With the Michigan personal property tax exemption, select businesses are instead subject to a statewide special assessment, ranging from $0.9 to $2.4 million, to fund essential services levied by local governments.

• With the State Essential Services Assessment (SESA) the Michigan Strategic Fund (MSF) may choose to exempt or reduce the Assessment for projects that create jobs and/or private investment in Michigan through the SESA Exemption or the Alternative State Essential Services Assessment Incentive. This is required for manufacturers that do not pay personal property tax on eligible manufacturing personal property.

• The Jobs Ready Michigan program helps meet the talent needs of companies that are expanding or relocating to Michigan. The program is designed to be flexible and responsive to the specific talent needs of companies and to address the costs associated with recruiting and training individuals for occupations that are high-wage, high-skill or high-demand.

• The Michigan Business Development Program is designed to provide grants, loans or other economic assistance to businesses for highly competitive projects in Michigan that create jobs and/or provide investment.