“Utility availability for industrial usage can always be secured at any given community.” While this prevailing thought may be correct in many instances, the time and cost to secure services at a property will vary considerably from one community to the next.

“Utility availability for industrial usage can always be secured at any given community.” While this prevailing thought may be correct in many instances, the time and cost to secure services at a property will vary considerably from one community to the next.

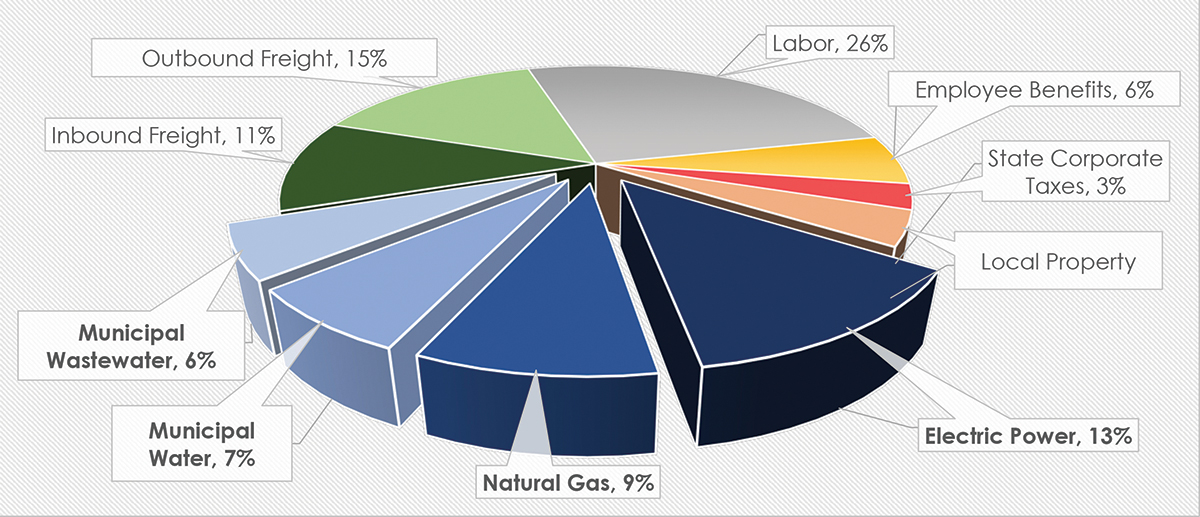

For a standard industrial plant, it is estimated that up to one-third of the total annual operating costs are associated with utility usage.

There are also times when utility costs can be even higher if the processing requires a considerable level of a specific utility such as water and wastewater for a food processor. Given all the considerations that go into industrial expansions, companies must not overlook communities that offer significant operational savings for electric power, natural gas, water, wastewater and communications.

There are several ways a company can determine the friendliness of a community or utility service provider. Knowing the attributes that make a community utility-friendly will help filter out those communities that aren’t the right fit from the beginning.

A utility-friendly community has the following attributes:

• Ample reserve capacity (30 percent is recommended) of municipal water and wastewater allocated for future community growth.

• Planned industrial parks containing a looped water and wastewater system throughout the property for consistent and reliable utility flows.

• Constructed industrial parks with a centralized stormwater system in place to serve both current and future industrial development.

• Good relationships with local private electric power and natural gas providers.

• Aggressively monitors and requests the necessary expansions by electric power and natural gas providers for future industrial development.

• Favorable water and wastewater connection, impact or tap fees for new industrial development.

• Reasonable or no effluent surcharges for those industrial users with higher than average effluent discharge levels.

• Electric power providers with a plan in place to add future or upgrade current substation(s) as industrial districts expand.

• Municipal service providers with a plan in place (such as securing right-of-way for line expansion and initiating pre-engineering studies to extend services) to expand water and wastewater systems for future development.

• Municipal service providers with a plan in place (such as securing right-of-way for line expansion and initiating pre-engineering studies to extend services) to expand water and wastewater systems for future development.

• Local utility providers that have exhibited little or no rate increases over the past five-year period and have no rate increases planned for the immediate future.

• Communication providers who have advanced technical services, including fiber-optic capabilities.

Communities that exhibit these traits are out there. However, it is up to the company to conduct thorough research to properly vet communities to uncover the best location for a future industrial operation.

To secure the best location that satisfies a company’s expansion needs, there are three recommended steps to evaluate a community’s utility infrastructure:

1. Initiate detailed research to understand preliminary utility needs for the operation’s startup, as well as forecast potential future needs—five years or longer—based on possible expansion plans.

2. Perform a comprehensive screening process to match the company’s utility needs with a community that appears to best satisfy the requirements.

3. Conduct field investigations to secure a community that provides a company’s utility needs at a reasonable cost and a reduced level of risk.

Determine the Need by Conducting Research

Based on the decision that plant expansion is necessary, a company must gain a clear understanding of its utility requirements. In many instances, potential plant utility requirements can be estimated by obtaining utility consumption levels from existing operations and modeling these numbers based on estimated plant size or production output for the new facility. If the proposed plant utilizes a new process technology or alternative production line, the company may need to obtain the advice of a design and engineering firm with an understanding of the company’s process and machinery for good utility usage estimation.

To comfortably estimate utility consumption levels, volumes and usage, a company must consider key operational factors to determine utility requirements at startup and forecast any potential future needs. Some of the critical factors used to develop these utility estimates include daily hours of operation, shift schedule and duration, employee estimates per shift, proposed product output and process machinery used.

Critical information that must be addressed early in the analysis are:

Electric Power

• Determine the maximum rate of electricity usage over a 30-minute interval, denoted as kW demand.

• Estimate the monthly consumption levels, expressed as kWh per month.

• Establish the required voltage to operate machinery.

• Identify machinery susceptible to power interruptions.

Based on the volume of electric power required, primary transmission service may be a viable option over distribution (also referred to as secondary) service. Primary transmission service is typically a viable option once the kW demand exceeds 5,000 kW but is also determined by individual electric power providers.

Natural Gas

• Estimate the monthly volume required for processing and space heating, expressed in therms or MCF (thousand cubic feet).

• Determine the line pressure, in psig, necessary for the operation.

• Decide whether a firm (non-interruptible) supply of gas is required for the operation.

Water

• Estimate the initial daily requirement, expressed in gallons per day or month.

• Identify peak demand, expressed in gallons per minute, over a 60-minute interval.

• Establish special water requirements and chemicals, temperatures or mineral composition to avoid anything that may negatively impact production.

• Determine the preferred flow rate.

Wastewater

Wastewater

• Estimate the initial daily discharge, expressed in gallons per day or month.

• Identify expected discharge levels, including effluents, usually recorded in milligrams per liter (mg/L), such as organic materials (BOD and COD); total suspended solids (TSS); fats, oils and greases (FOG); and pH levels.

• Based on potential discharge levels, determine whether an onsite pre-treatment system should be

considered if required by the community.

Communications

• Verify necessary communication requirements, including the need for fiber optics at the site.

• Establish the preferred communications carrier.

Secure the Best Community Match During In-House Analysis

After utility requirements are determined, a company will begin an in-house evaluation within a desired geographic search area to screen potential properties and communities based on utility and other project requirements to find best-fit locations.

To initiate the screening process, a company should complete a document discussing key location considerations for the project, referred to as an RFI (Request for Information). RFIs are usually submitted to state, regional and local Economic Development Organizations (EDOs) within the target search area for the potential new operation.

The RFI includes pertinent utility information, including volume and consumption considerations established previously. The primary goal of this effort is to receive a list of the best properties for the proposed operation. Another purpose of the RFI is to request utility cost information, in the form of estimated bills, from each provider. In addition to estimated utility bills, other pertinent details include natural gas, water and wastewater line sizes and their proximity to the subject property.

The RFI includes pertinent utility information, including volume and consumption considerations established previously. The primary goal of this effort is to receive a list of the best properties for the proposed operation. Another purpose of the RFI is to request utility cost information, in the form of estimated bills, from each provider. In addition to estimated utility bills, other pertinent details include natural gas, water and wastewater line sizes and their proximity to the subject property.

Locations are rated and ranked on how well each will satisfy the utility requirements for the proposed operation. Once properties are ranked, field investigations are performed to see how well they align with the operational needs of the plant. Depending on the project and geography involved, field investigations for five or more locations in a minimum of two states are recommended.

Conduct Field Work to Discover the Best Options

Once the properties have been inspected, in-person meetings are scheduled with representatives from each utility provider to discuss the locations and review any questions or concerns encountered during the investigation. During each meeting, utility representatives are asked to explain and illustrate, on a map, the location and line size of the water, wastewater, and natural gas serving the property being considered.

For electric power, representatives are asked for a copy of the provider’s power grid map in electronic format. This map gives an overview of the power network and available voltage emanating from the provider’s substations and transmission lines.

Meetings with utility representatives are the best time to review estimated annual and one-time costs for each property. As follow up to these meetings, a complete copy of all estimated cost information is requested in writing on the provider’s letterhead. This level of documentation affirms each provider’s understanding of the project and willingness to provide service at the required capacity for a specific rate.

Upon returning from field investigations, detailed cost comparisons, including all annual and one-time utility costs for finalist properties, are completed and reviewed. The sites are ranked. Only the top two or three locations that best meet search criteria are considered for the new expansion. Not all properties and communities will be a perfect match; there will be deficiencies and risks to overcome, even with locations that score high in the screening process.

The next step is to discuss site deficiencies with the state, local and utility EDOs and identify the best way these groups can assist in overcoming any identified gaps. This step is often conducted during the final site due diligence assessment and incentives negotiations. As suggested earlier, this is the best time to correct any utility flaws or deficiencies with state and local EDOs and utility providers. All utility concerns must be addressed before a purchase agreement is finalized.

During field investigations, important information often emerges that draws attention to a community and a specific property that possesses utility-friendly characteristics. Some areas have excess utility infrastructure that has been abandoned because of a manufacturing plant closure or relocation and is now available and waiting for new development to occur.

Communities with a history of textile or apparel manufacturing are often cited as excellent targets for a company searching for a new location. These communities often contain large utility capacities, especially for significant water and wastewater users. When considering wastewater specifically, the need for discharge effluents in a system can promote the health of microorganisms used to break down waste. Communities with this need can accept large discharge volumes, which yields a strategic advantage for companies like food processors with high levels of biochemical oxygen demand (BOD) and suspended solids (SS).

Underutilized utility infrastructure, especially for water and wastewater, is a tremendous asset to economic development marketing efforts and can make a difference in the ultimate property selection for a company looking to expand. In addition to water and wastewater availability and infrastructure, a utility-friendly location must have low to moderate one-time utility connection or impact fees for water and wastewater usage, as well as an overall reasonable operating cost structure with little to no projected future cost increases at the municipal level.

These types of positive community attributes, especially when it comes to low utility operating costs, ample availability and ability to handle waste effluents, will elevate an area into a true utility-friendly community. T&ID

Breaking Down Operating Costs

In conducting a detailed community cost analysis, overall utility costs are typically the third most important general operating cost category for most manufacturing operations. Labor and employee benefits comprise the highest operating expense, followed by transportation and logistics, then utilities. However, for many manufacturers, including chemical, pharmaceutical and food processors, the importance of utility availability and cost often emerges as the second most important annual operating cost, surpassed only by labor.