Distribution center design is evolving, and in large part, it’s changing to address the critical need that companies are challenged with today: attracting and retaining good people.

Distribution center design is evolving, and in large part, it’s changing to address the critical need that companies are challenged with today: attracting and retaining good people.

A recent distribution center marketing brochure had just three words on its cover: “human centric design.” Why choose to market a distribution center with that as your main attribute? Well, this is no longer your grandfather’s distribution center.

In the past, the distribution center site selection and design business was fairly simple. Put down a concrete slab, tilt up four walls, throw in some racking and hire some people to start moving boxes in and out.

Not today. As everyone knows, the world of supply-chain management has changed significantly with the rapid advances of both e-commerce and technology. This in turn is impacting the way companies look at their distribution networks as well as the industrial building design.

Everyone in the labor force would likely prefer to work in an attractive, productive, comfortable and safe space. That being the case, why haven’t those attributes, and other amenities generally found in an office environment, typically been incorporated in industrial distribution center designs?

We’re going to focus on how companies are evaluating their distribution networks, the influencers of site selection and the changes going on relative to distribution building design today.

Understanding the Costs

Understanding the Costs

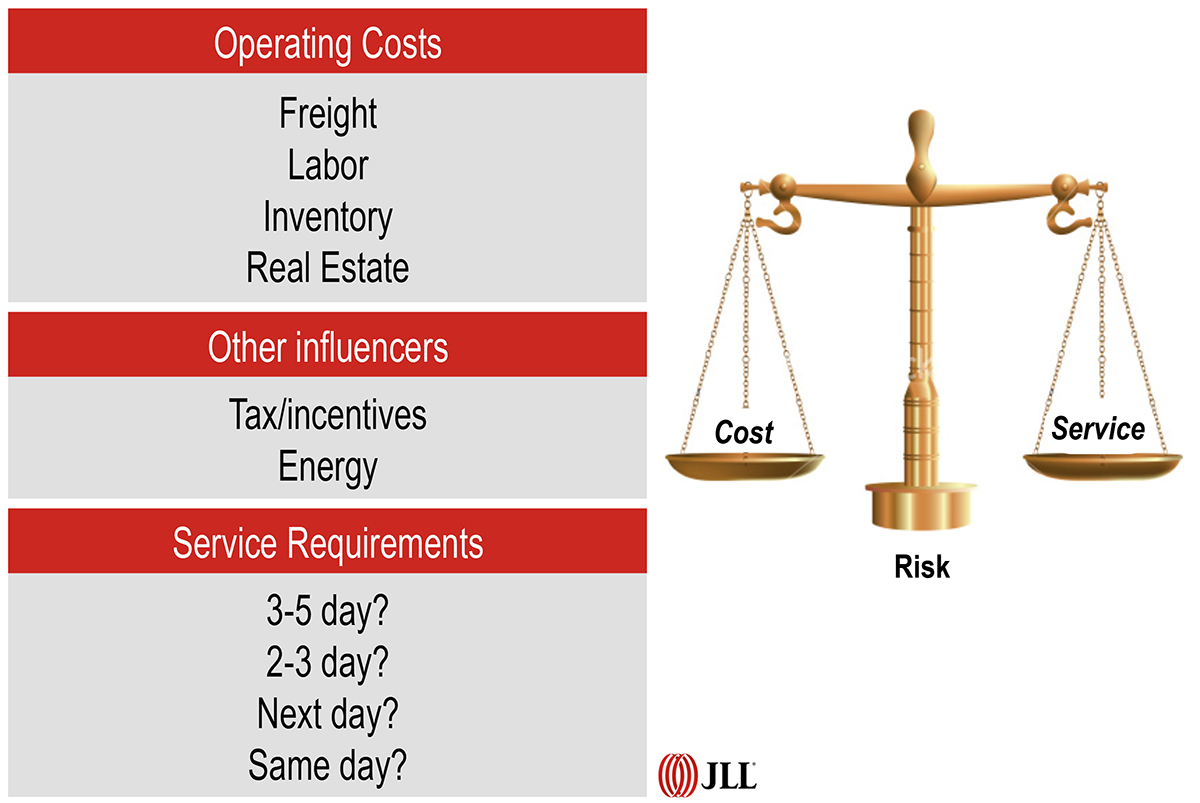

The methodology behind how companies go about determining their distribution strategy—How many warehouses? Where should they be? How big?—begins by first understanding all of the cost components as well as customer-service requirements.

When looking at the total operating cost of a distribution center, the biggest costs include transportation (goods in and out), labor (handling), inventory carrying costs and rent (lease expense).

Transportation costs have historically been the largest consideration to site selection. The higher freight costs go, the math would suggest having more facilities closer to your customers.

Labor has also been a significant cost consideration, but was not historically a huge influencer as the skill sets and number of people needed to staff even a fairly large distribution center were not hard to obtain. This has changed dramatically, as we’ll see in more detail below.

Inventory carrying costs are influenced by the number of facilities in the network. If you have one facility, all your inventory is located there. More facilities mean more inventory, not necessarily twice as much, but additional safety stock that you will be carrying, and there is a cost associated with that.

Rent or lease expense typically represents just 3 to 5 percent of the total operating cost, but it is clearly important to get your building located in the right place.

These cost considerations are all “balanced” by customer-service requirements, which are changing rapidly.

Increased Service Expectations

Increased Service Expectations

The rapid emergence of e-commerce, as well as the impact Amazon has had with the introduction of its Prime same- to two-day delivery service, helped to usher in a whole new set of increasing customer-service expectations. Gone are the days of getting away with three- to five-day delivery. Two-day delivery is the new norm … at least for today.

As customer-service expectations have increased, this has changed the way companies evaluate their distribution networks. Tighter delivery times drive companies to have more facilities closer in proximity to their customers. This is true for business-to-consumer (B2C) companies, but also has had a big influence on business-to-business (B2B) companies as well.

The B2B marketplace is much larger in size than the current B2C and has also been impacted by the “Amazon effect” and increasing customer-service expectations. The supply-chain networks for every business must be re-examined as e-commerce continues to evolve and influence customer expectations.

As supply-chain practitioners understand, getting the optimal supply chain is a delicate balance of cost, service and risk-management tradeoffs.

Freight volumes are at an all-time high and therefore freight costs are up across all modes of transportation today (e.g., trucking, rail, ocean, intermodal), and that trend is expected to remain into 2019. Labor costs are also at an all-time high. Amazon made headlines in October when it announced it would voluntarily move to a $15 per hour minimum wage. These costs, coupled with the fact that industrial real estate (distribution center space) vacancy rates are at an all-time low, have driven up lease costs significantly, and that assumes you can actually find the space you need in the location you desire. All these factors have supply-chain practitioners working overtime to try to make the best site selection decisions.

Freight volumes are at an all-time high and therefore freight costs are up across all modes of transportation today (e.g., trucking, rail, ocean, intermodal), and that trend is expected to remain into 2019. Labor costs are also at an all-time high. Amazon made headlines in October when it announced it would voluntarily move to a $15 per hour minimum wage. These costs, coupled with the fact that industrial real estate (distribution center space) vacancy rates are at an all-time low, have driven up lease costs significantly, and that assumes you can actually find the space you need in the location you desire. All these factors have supply-chain practitioners working overtime to try to make the best site selection decisions.

Labor: A Major Influencer

Labor has become one of the biggest influencers on supply-chain decision-making today.

The rapid growth of e-commerce has changed the game of fulfilment. In a “traditional” distribution center—one that would replenish retail stores, for example—a 500,000-square-foot facility might employ 100 to 150 workers.

In a similar-size building, but one that is focused on fulfilling individual customer online orders, it might employ three to 10 times as many people (during peak seasons) and require a higher skill set. Movement from palletized shipments to more frequent, smaller, individual orders results in more “pick and pack” or case picking, which is far more labor intensive.

This, along with a robust economy and an unemployment rate of just 3.9 percent (as of late 2018), has made attracting and retaining labor one of the most influential determinants of distribution-center site selection today.

With these challenges in mind, our team interviewed corporate occupiers, investors and developers of industrial real estate to uncover some of the latest innovations and trends.

Corporate occupiers have always understood and valued well-designed office buildings and floor space. Floor-to-ceiling windows, good ventilation/air conditioning, white noise, as well as beautiful, modern common areas have been popular for years because they are critical to recruiting and retaining employees.

So why hasn’t this been the case for industrial real estate? Why not employ similar ideas when it comes to distribution centers?

Founded in October 2014, the International WELL Building Institute (IWBI) is leading a global movement to transform buildings and communities in ways that help people thrive. Its WELL Building Standards are revolutionizing the way people think about buildings.

IWBI explores how design, operations and behaviors within the places where employees live, work, learn and play can be optimized to advance human health and well-being. The IWBI suggests there are seven categories or features of a “well facility”: air, water, nourishment, light, fitness, comfort and mind.

These seven features are focused on the promotion of employee health, well-being and enrichment. The outcome? Higher retention rates and more productive employees. Bingo!

What Do Employees Want?

Based on interviews on the topic of design trends with corporate occupiers as well as leading industrial real estate investors, developers and builders, we’ve learned that while improvements are being made in working conditions, economics still play a major role. That said, various innovations are being adopted to address and become more competitive relative to the labor challenge. Here is the “Top 10” list:

1. Trend toward more goods-to-person automation and, in some cases, advanced robotics. These material-handling systems can significantly reduce walking, bending and lifting required to fulfill orders and reduce human body stress and fatigue while increasing productivity.

2. High-quality common areas, multiple break rooms and cafeterias are a must. Subsidized food service along with simple things, like plenty of refrigeration and microwave oven capacity, are also well-received by employees. Common areas that extend outside the building for exterior enjoyment including patios, grilling areas and even fire pits add flare to special employee events (work anniversaries, birthday celebrations, employee-of-the month, etc.)

3. Exercise amenities such as gyms, locker facilities, walking paths, jogging tracks and even more elaborate amenities such as rock-climbing walls, are well-received by employees. (Yes, rock-climbing walls.)

4. Locating core warehousing elements (e.g., restrooms, break rooms, phone charging stations) within proximity to employee work-flow areas with the goal of creating the shortest travel times will improve employee efficiency, productivity and morale.

5. Ample and convenient parking located in areas that minimize walking time into the building and avoid heavily trafficked areas for both trucks and passenger cars. It may sound basic, but it’s more important than ever in facilities employing three to 10 times as many employees. Parking for employees needs to be separated from trailer or loading dock traffic.

6. Proximity to public transportation. This is especially critical in more urban environments where many potential workers do not own a car or for safety concerns. Industrial developers are working more closely with local jurisdictions to increase or add bus/mass transportation services (bus and train stops) to facilities.

8. Improved connectivity inside the building, with multiple WAPs (wireless access points) and wireless RAF antennas to allow for better/more consistent access to employees working in large distribution centers that have had poor overall connectivity in the past. The focus has long been on ensuring connectivity for warehousing systems/processes, but there is now an additional focus on the employee experience (via better human productivity) while in the workplace.

9. Better lighting as well as increased natural light by designing additional glass lines and skylights at and above the dock window line, as well as mounted lights on equipment, so employees do not have to strain their eyes to read barcodes or order labels when picking products in densely stored areas.

10. Improved ventilation and air circulation through improved ridged insulation, as well as fans mounted on various warehousing equipment and efficient HVAC where appropriate, all vastly improve the employee working environment.

It’s clear that distribution network strategy, site selection decision-making and industrial facility design will need to evolve to address the critical need companies are challenged with today—attracting and retaining good people.

Designing and building attractive, productive, healthy and comfortable industrial buildings that incorporate similar amenities typically expected in office buildings is inevitable. Companies are already seeing “human centric design” in industrial facilities, and can expect this trend to increase—because it’s the right direction. T&ID