In the United States, research and development is a huge economic driver at the federal, state and local level. According to a recent report from the Battelle Institute, the U.S. was expected to spend approximately $405.3 billion in R&D in 2011, about 2.4 percent over what it spent in 2010. The U.S. accounts for about one-third of all global R&D spending, which was forecast to reach $1.2 trillion in 2011.

|

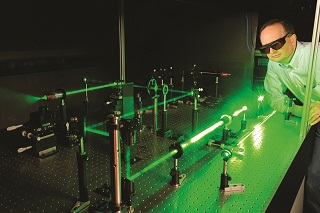

| Photo courtesy of Hergen Eilers |

Throughout the country, this R&D is making a huge impact on economic development, spurring the growth of businesses ranging from high-tech startups to corporations to family farms.

Some regions have even experienced enough critical mass from R&D that they’ve become research hubs. By working to tie together public and private resources, they are seeing a snowball effect on the economy, with business startups and even more money flowing into academic research.

The Hub Effect is Creating R& D Centers

From Boulder to Little Rock to Spokane to the state of North Carolina led by the Research Triangle area, local leaders have been working tirelessly to turn their regions in R&D centers.

Boulder, Colorado

Boulder, Colorado is home of research powerhouse University of Colorado (CU). Thanks to CU’s strong tech transfer program, a number of businesses that spun out of university-driven research are bolstering the economy throughout the state.

As part of this commitment, CU is opening up the BioFrontiers Institute. To combat the stagnation that can stem from individual departments working in siloes, the BioFrontiers Institute will bring together researchers in fields such as mathematics, computational science, biology and biochemistry to jointly work on projects. It will house more than 600 faculty, staff and students from nine departments when it opens in early 2012.

Bronson R. Hilliard, director of media relations and spokesperson for CU Boulder said, “What Boulder is doing with biotech is what we did with aerospace in the ‘60s and ‘70s. We’re now number two or three in aerospace, which wouldn’t have happened without CU. Today, we’re focusing on biotech.”

While R&D is thriving at CU, a big reason this technology is becoming commercialized is the university’s strong tech transfer program. Since 1994, it has worked with 114 new companies, 91 that are still operational and 85 of which have key operations in Colorado. These firms have attracted more than $1.3 billion in financing from sources such as federal grants and venture capital.

Dave Allen, Associate VP for Tech Transfer at the University of Colorado, explains, “The commercial potential of research from university labs is usually four-to-ten years out. What’s necessary is for us to connect the technology with a visionary who understands the local community, the technology and gets the market vision.”

Little Rock, Arkansas

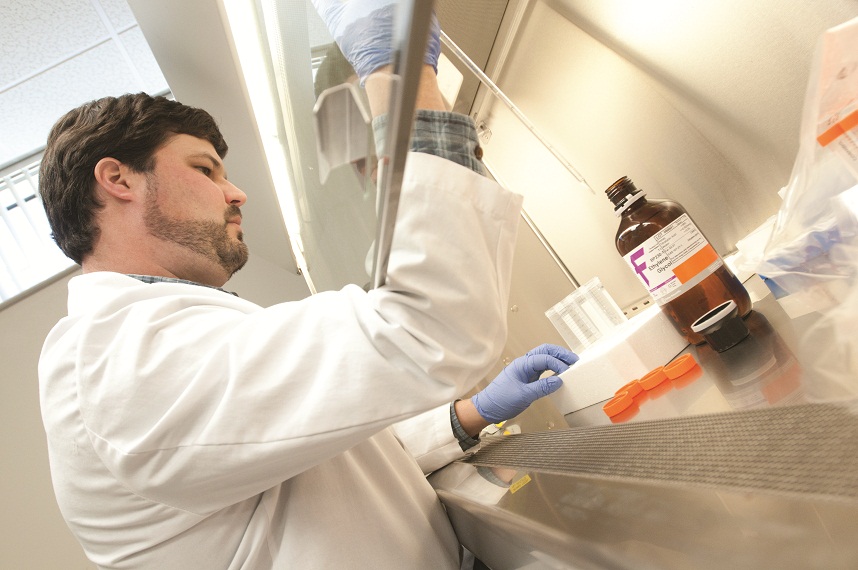

Another hub of biotech is the Little Rock, Arkansas region, anchored by the University of Arkansas for Medical Sciences (UMAS), the Nanotechnology Center at University of Little Rock (UALR), and the Food and Drug Administration’s National Center for Toxicological Research (NCTR) that is 35 miles away in northern Jefferson County, Arkansas.

UALR is a world-player in nanomaterial research while UAMS is the major academic and research medical center in the region. According to Michael G. Douglas Ph.D., director of the UAMS BioVentures Technology Licensing and Life Science Incubator, the institution’s funding more than doubled to $240 million in 2011.

“That reflects the good science done here as well as our emphasis on telemedicine, which is reaching remote areas to provide medical care and needed in the state,” Douglas said. “At UMAS, we’re trying to blend best of nanosciences at ULAR with our research of life sciences for the use of these materials.”

As a result, the area is a hub for research and treatment of multiple myeloma. Not only do people come from around the world for treatment, local company and incubator resident Myeloma Heath Inc. is leading the way in the management and treatment of the disease throdugh genetic testing.

|

| Photo courtesy of the Bioventures Technology Licensing and Life Science Incubator at the University of Arkansas Medical Sciences |

“With the National Center for Toxicological Research so close, there’s a perfect storm for research that drives commercialization. We’re trying to make the world aware of what’s here,” added Jay Chesshir, president and CEO of the Little Rock Regional Chamber of Commerce.

This perfect storm is the reason behind the $55 million, 30-acre, 100,000 sq. ft. research and technology parks that is in the works. Located within a five-minute’s drive of UAMS, UALR and the Arkansas Children’s hospital, it will focus on nanotechnology and is being supported by a $22 tax referendum passed by voters in September, 2011. Construction for the first phase is expected in 2014.

“It will be one of the most important regional economic engines in recent history,” said Douglas. “We’re creating a real draw from companies who want to come here, close to our best and brightest.”

Leaders in nearby Jefferson County, where the NCTR is located, are also capitalizing on this momentum. They are planning to build a high-tech campus called the Bioplex next to the NCTR and its 150 researchers and more than 500 personnel with a broad array of toxicological expertise.

“Studies verified that a draw for high-tech locations was a cluster of entities with highly educated workers and a research environment,” said Lou Ann Nisbett, president and CEO of the Alliance of Jefferson County. “The Bioplex is ideally located for companies interested in taking this cutting-edge research into commercialization.”

Arkansas governor Mike Beebe and FDA Commissioner Margaret Hamburg signed a Memorandum of Understanding in August, 2011 solidifying a partnership between the state and the facility. This furthers the research on the toxicology of products and processes associated with nanotechnology.

“The NCTR is a unique federal resource with state-of-the-art equipment and capabilities on the cutting edge of developments in medical and food science. The richness of this resource provides a seedbed for new solutions to problems and thus new business development,” said Art Norris, interim NCTR director.

Spokane, Washington

Spokane, Washington is another hotbed of R&D.

“Health sciences, which are driven by R&D, are 20 percent of our economy,” said Robin Toth, VP of Business Development at Greater Spokane Incorporated. “We’re a regional hub that serves over 1.4 million people in the surrounding states and Canada. By the year 2030, it is projected to have an impact of $2 billion and we’re doing everything we can to move this industry along.”

|

| Photo courtesy of Tom Chastek |

Washington State University (WSU) Spokane plays a big part, with its world-class Sleep Research and Performance Center and a new Biomedical & Health Sciences building that is slated to open in 2013. WSU is also using its research to solve local business challenges at its Applied Sciences Laboratory (ASL) with a multidisciplinary team of entrepreneurial scientists and engineers.

ASL has worked closely with Avista, a Spokane-headquartered utility that provides electric service to more than 600,000 electric and natural gas customers. Avista has supported and partnered with ASL since its inception and is now the recipient of the lab’s expertise in providing better solutions to its challenges.

One project involved creating new, environmentally friendly hydraulic oil for its hydro plants. Researchers developed canola-based oil that is both “green” and stimulates the local economy, since canola is grown in the region.

“Because of ASL, our engineers can easily collaborate with academic types – and they’re coming up with ideas we haven’t had before. You certainly don’t get that with research at a distance. This partnership has great potential benefits,” said Dave Holmes, manager of applied R&D at Avista.

North Carolina

On the east coast, North Carolina is another R&D hotspot, led by the Research Triangle of Raleigh, Durham and Chapel Hill. The state has more than 530 life-science companies employing more than 59,000 people. For nearly three decades, the North Carolina Biotechnology Center has facilitated biotechnology education, research, and business development in North Carolina.

One major area of focus at the North Carolina Biotechnology Center is on agricultural biotech. The agriculture sector pumps $70.1 billion annually into the state’s economy, employing 17 percent of the workforce and most of the largest Ag companies, including Syngenta, Bayer, BASF and Monsanto have research facilities in state.

“At the North Carolina Biotechnology Center, our goal is to link various aspects of research in the state, bring parties all together and make it happen. Biotechnology is a big economic engine in the state,” said Paul Ulanch, Ph.D., crops development director. “The Center was the first nonprofit organization in the country promoting economic development around biotech. Since then, other states have developed similar models,” he added.

Ag Biotech Research is Driving Business

Throughout the country, agricultural research is having a huge impact on business ranging from mom-and-pop farms to biotech startups hoping that plants hold the key to curing cancer.

In west Texas, about an hour south of Lubbock, Lamesa is home to the Agricultural Complex for Advanced Research and Extension Systems (AG-CARES), a full-scale research farm run by Texas A&M University. This 248-acre research farm gives agricultural scientists the opportunity to test new technology on the crops produced in the Southern High Plains such as cotton, peanuts and grain sorghum.

“We’re helping the area growers make better decisions on what they grow to get the best results,” said Jaroy Moore, resident director at the Texas A&M AgriLife Research and Extension Center.

One area where AG-CARES has changed farming practices is in how nitrogen soil sampling is done. Moore said that area farmers used to take six-inch-deep soil samples to test for nitrogen to determine how much fertilizer they needed to add. The center’s research found that by taking deeper two-to-thee foot samples, the area’s soil contained adequate nitrogen, eliminating the need to add more.

“This is a big cost savings, as well as a positive impact on the environment,” said Moore.

In Pacific County in southwest corner of Washington State, Ag research is having an equally big impact, this time on crops such as cranberries and oysters.

“We draw a lot of university researchers here to study these crops in their natural environments to help make them hardier,” said Cathy Russ, director of the Pacific County Economic Development Council. “Such an extreme talent pool, coupled with our low cost of doing business, makes it beneficial in many ways for R&D to start up here,” she added.

Kim Patton, Washington State University extension professor, is one of the researchers who is helping make cranberry and shellfish farming viable in the region.

“Shellfish is a $70 million industry in Pacific County. Because of pests such as burrowing shrimp and invasive seagrasses, many farmers have had to walk away from their businesses,” said Patton. “With no control, that industry will essentially disappear. We’ve found solutions and are working to getting them implemented.”

Cranberries are another focus of Patton. His germplasm research is helping the areas’ 110 cranberry farmers find ways to control weeds and choose hardier varieties that increase yields.

And, in North Carolina, Ag research from NC State in Raleigh and support from the state’s Biotechnology Center is the basis of NanoVector. The company is using tobacco plants to make nanoparticles of a common plant virus to deliver chemotherapies.

“I find it ironic that we’re using a plant that causes cancer to cure cancer. But without it, you can’t build a cost-effective nanoparticle-based drug,” said CEO Al Bender, PhD.

Local Research Drives Business Development in the Vicinity

Local R&D is also spurring business development at businesses in both research hubs and small communities with strong ties to higher education.

In central Wisconsin’s Portage County, several businesses are thriving, partly because of the research and support they receive from the strong University of Wisconsin system.

One is Pointe Precision, a company with 150 employees and 11 on-staff engineers.

“Our precision machining techniques allow us to efficiently produce aerospace components that are instrumental in the fuel control systems of major manufacturers' aircraft engines. You will also find components we’ve produced in the braking systems of NASCAR and emergency response vehicles, medical devices, industrial power generation and other systems requiring critical tolerance qualifications,” explained Scot Barton, VP of sales and operations.

The company has a partnership with the University of Wisconsin’s Plattville’s engineering program to recruit engineers through a co-op program.

“It’s a great way to get highly skilled, home-grown talent,” said Joe Kinsella, president & CEO. “Our engineers are able to work hand-in-hand with our customers, improving their designs to improve quality and find cost savings.”

Marten Machining is another company in Portage County that has turned R&D into business success. It specializes in CNC machining of various parts including tools and fixtures for manufacturers and complex or specialized machined components. With its close relationship with the University of Wisconsin, it has machined parts for UW-Madison’s ice core drilling project in Antarctica and for a new, infrared device at its South African’s observatory.

“We have also done a large amount of work for the University of Wisconsin system making parts for various research projects,” said David Martin, vice president there. “Portage County’s central location puts us in proximity with the places where R&D work is being done.”

Like at Pointe Precision, Marten Machining finds a majority of its employees through the UW and strong local tech school system.

“The Wisconsin Institute for Sustainable Technology (WIST) at the local University of Wisconsin-Stevens Point is developing new uses for biomaterials with the aim of transferring technology to industry in order to grow the economy and add jobs,” said Lori Dehlinger, executive director, Portage County WI Business Council.

In Boulder, InDevR sprung out of research from CU in 2003. The company has commercialized the Virus Counter and the ampliPHOX microarray detection system that quantifies virus particles in a sample in just a few minutes, as compared to plaque titer which takes days.

“Keeping the business in Boulder makes sense,” explained COO and co-founder Laura Kuck, PhD. In addition to the attractive quality of life the area offers, “There is the existence of an established science community with many networking opportunities, along with an abundance of talented and enthusiastic scientists and engineers who came to Boulder for an education and do not want to leave,” she said.

A supportive, research-driven climate also lures – and retains –companies. HaloSource develops water purification and clarification solutions for use worldwide and operates a testing and small-scale production facility in Pacific County, Washington.

“Our facility is a conduit from R&D to commercialization,” said Devon Brown, director of operations. “We have a good core workforce there, the lease is reasonable and there is a very tight-knit community that is supportive of business.”

According to the Battelle Institute, R&D accounts for 2.7 percent of the GPD (gross domestic product) in the U.S. By impacting everything from the nation’s health and food chain to manufacturing, it’s no wonder why communities from coast to coast are finding R&D the key to business and economic development.