Innovative workforce training programs are a driving force to help businesses—and communities—thrive. From the federal level down to county and city levels, these programs are connecting employers to a highly skilled workforce. Take a look at some notable examples around the country.

Sandusky County Economic Development Corporation, Ohio

Growing a workforce from a young age

Sandusky County is a growing business hub strategically located in Northwest Ohio, offering businesses access to a large workforce.

While many communities see a shortage of skilled workers, Sandusky County has been proactive at implementing strategies to overcome the shortage. One way is through the THINK Sandusky County Workforce Development Initiatives, an ongoing initiative of the Sandusky County Economic Development Corporation (SCEDC) in conjunction with local community and business partners. Its mission is to overcome barriers to employment and address gaps in Sandusky County’s workforce pipeline by programs and different outreach efforts. It does so by offering workforce training to young people as an alternative to college.

The program showcases opportunities in the manufacturing industry such as apprenticeships, internships, tuition reimbursement and job advancement. THINK also works closely with the area’s school superintendents, principals and guidance counselors, connecting them with local manufacturers so they are aware of available careers, the skill sets required and earning potential—so they can share it with their students.

“THINK Sandusky County is vital to attracting companies to Sandusky County because we are creating a pool of workers with these programs for the younger generation,” says Beth Hannam, executive director at SCEDC. “Our focus is to help existing businesses stay competitive. When working with potential new businesses, we inform them of all the programs offered and connect them with the correct community partners to help fill any immediate needs.”

One firm that is benefitting from these programs is Century Die Company, which has been providing molds and tooling for more than 70 years. According to General Manager Tim Myers, in 2011, the company had an aging workforce with only nine millennials and no apprentices. Today, the company employs 34 millennials and 12 apprentices, and he attributes this to the area’s youth awareness initiatives such as THINK.

Limestone County Economic Development Authority, Alabama

A close partnership with local manufacturers and training programs

Limestone County, Ala., is one of the fastest growing counties in the state. This centrally located community is less than 100 miles from Birmingham and Nashville and known for its highly educated workforce. According to Bethany Shockney, president and CEO of the Limestone County Economic Development Association, “We have one of the largest career tech offerings in the state.”

The area is home to Calhoun Community College, the largest two-year college in the Alabama College system. It offers the Alabama F.A.M.E. (Federation for Advanced Manufacturing Education) Advanced Manufacturing Technician Program (AMT), one of the many workforce training programs in the area. F.A.M.E. includes a two-year associate degree that combines cutting-edge curriculum with a paid working experience.

Another program is the Robotics Technology Park (RTP), a $73 million investment that’s a collaboration between the state of Alabama, Alabama Community College System, AIDT and robotics industry leaders across the nation. Located across the street from Calhoun Community College, the RTP consists of three individual training facilities, each targeted to a specific industry need.

“Companies love being able to train students in the culture of their particular industry and students benefit from workplace training plus lab-based instruction back in the classroom,” says Shockney.

Mazda Toyota Manufacturing in Huntsville is an example of a local manufacturer benefitting from the F.A.M.E program. The company currently sponsors 14 students from the Advanced Manufacturing Technician program and has the option to hire them full time if they complete the program successfully. The company adopted this training model for its other locations.

“Programs like F.A.M.E. prepare individuals for careers in industry,” says Toni Eberhart in corporate communications at Mazda Toyota Manufacturing. “The partnership between educational institutions work hand in hand to ensure that anyone with an interest and motivation to participate in our growing economy has that opportunity through the careers provided by Mazda Toyota Manufacturing. We leverage these programs and partnerships to meet our workforce needs.”

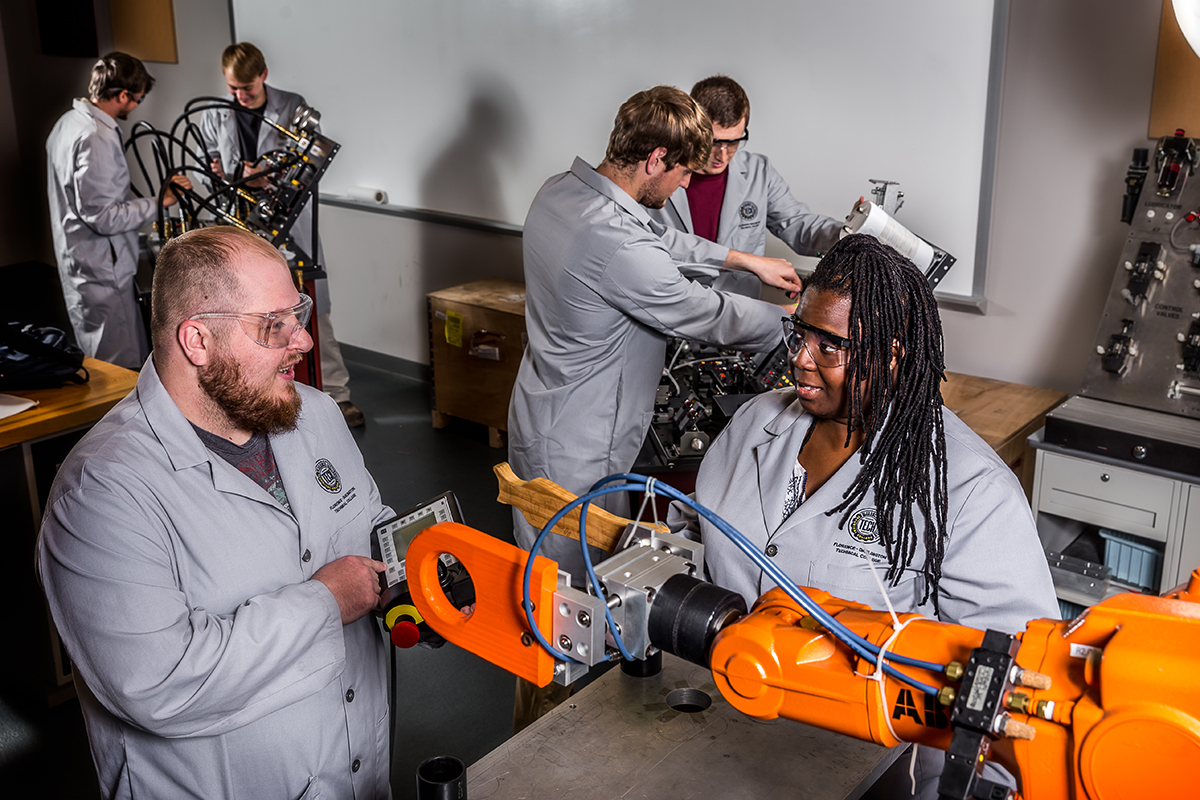

North Eastern Strategic Alliance (NESA), Florence, South Carolina

Numerous workforce programs are a boon to job-seekers and companies

In the northeastern corner of South Carolina, the North Eastern Strategic Alliance (NESA) spans nine counties. The region utilizes a variety of workforce training programs and assistance offered by the state, including ReadySC.

ReadySC offers customized recruiting and training solutions to both existing and relocating companies, free if the company creates 10 new jobs per year. In addition, three universities and four technical schools in the area offer a vast array of programs that can cater to a company’s needs. This includes Southeastern Institute of Manufacturing and Technology (SiMT), a 189,000-square-foot advanced manufacturing center, Horry-Georgetown Technical College with two advanced manufacturing centers and the Continuum, a regional center for education and training in innovative and technical skills and workforce development.

“Every job that runs through one of the workforce programs changes a life,” says Jeff McKay, executive director at NESA. “Whether it’s free training through ReadySC, the statewide apprentice program Apprenticeship Carolina, on-the-job training and incumbent worker training offered through SC Works, a course through one of our technical colleges or universities, or any number of other programs, we see the impact in our communities every day.”

Groupe Beneteau is a French sailboat manufacturer located in Marion, S.C., that is taking advantage of these workforce training programs. The company has hired two apprentices through the Apprenticeship Carolina program and is also launching a three-week pre-employment training program in partnership with Florence-Darlington Technical College called “Beneteau Tech,” which combines hands-on and classroom training and a guaranteed job to everyone who completes the program.

“This customized training approach will yield the best results for developing this company’s entry-level workforce while offering a continuous path of opportunity for job-seekers,” says Marion County Economic Development Director Dr. Julie Norman.

Allamakee County Department of Economic Development, Iowa

Listening and responding to employers’ needs

In northeast Iowa, Allamakee County is known for its vibrant economy, a highly motivated and well-educated workforce, available and affordable building sites and construction, and a superior quality of life. It features a centralized U.S. location approximately three hours from Madison, Wis., and Chicago.

“We have employees who want to stay here and businesses that want to grow,” says Valerie Reinke, executive director at Allamakee County Economic Development & Tourism.

Allamakee County is looking to expand its supply chain clusters in advanced manufacturing, welding, fabricating and agriculture.

Northeast Iowa Community College (NICC), Allamakee Community School District and Allamakee County Economic Development & Tourism recently collaborated to renovate and re-open the Regional Welding Lab, located at a local high school. Northeast Iowa Community College began offering welding career pathway certificate classes held during the school day for high school students starting this past fall. In 2020, the program will expand to offer evening classes for adults.

“We listen to our employers,” says Reinke. “The workforce is out there and we try to meet their needs, along with the needs of our workforce to create something that is going to be a huge asset for our community.”

Missouri Department of Economic Development

Well-established workforce programs spur new investment in the state

Workforce is a key priority for the state of Missouri. Some of the key workforce training programs include Missouri One Start, Fast Track Workforce Incentive Grant and registered apprenticeships.

Missouri One Start is a new division within the Department of Economic Development with dedicated resources to assist companies recruit, train and upskill their workers. The Fast Track Workforce Incentive Grant is a new financial-aid program administered by the Department of Higher Education and Workforce Development. It ensures, when combined with other governmental financial aid, that tuition and fees are fully covered for adults wanting to pursue a certificate, degree or industry-recognized credential in an area designated as high need. In addition, the state’s registered apprenticeships keep the pipeline filled with skilled labor across a variety of high-demand jobs. Ranked second in the nation in the number of apprentices participating, this model for employment pays more as a worker reaches higher productivity levels.

When a recent distribution center moved to Missouri, the company was uncertain how they were going to recruit and train over 250 employees in a short four-month window. Experts from the Missouri One Start team met with the company to understand their challenges and provide a personalized workforce plan that addressed recruitment and outreach, applicant screening and onboarding assistance at no cost to the company. Once the employees were hired, the company received resources to meet their specific training needs, allowing them to streamline their workforce readiness and get up to speed faster. With the assistance of Missouri’s workforce programs, the company has exceeded its onboarding expectations and currently has more than 500 employees.

“Whether it’s a new company moving into the state or an existing company seeking to upskill their workforce, Missouri has seen growth in both capital investments and employee wages in local economies due in part to the workforce resources and incentives provided to companies,” says Peggy Smith, marketing and branding manager at Missouri One Start.

Warren County Economic Development Commission, North Carolina

Warren County Economic Development Commission, North Carolina

Retaining businesses by educating the local employee base

With approximately 20,400 residents, Warren County, N.C., is strategically located along the border of North Carolina and Virginia, only an hour from the Research Triangle. The region offers a variety of workplace training programs to draw and retain businesses.

Vance Granville Community College (VGCC) works with new, expanding and existing industries in providing customized training programs tailored to meet the needs of the industry and its employees. These programs are flexible in design to accomplish specific objectives and are jointly planned by company personnel and industrial training specialists from the college.

Another successful workforce program is NCWorks. Job seekers can search for jobs and create resumes, as well as find education and training. Employers can search for candidates, post jobs and explore labor market information. NCWorks also offers occupational skills training, on-the-job training, assistance with skills upgrading, entrepreneurial training and job readiness training.

According to Stacy Woodhouse, Warren County EDC director, many growing local companies take advantage of the customized training, including Glen Raven, a textile manufacturer well-known for its Sunbrella brand. “It helps with retention,” he says.

Another company that joined forces with VGCC for workforce development is Frigi-Temp, a commercial HVAC and refrigeration service that has served central North Carolina since 2001. The company created an apprenticeship initiative. Frigi-Temp CEO Cory Thornton says that he sought to partner with the college to help recruit new technicians to keep up with demand. The apprenticeship model involves a combination of on-the-job training coupled with formal education at VGCC. It offers students a straight path to career with little to no debt.

“Over the next few years, it’s estimated that there will be a shortage of 50,000 HVAC technicians nationwide, because the number of new people going into the industry isn’t enough to keep pace with all those who are retiring,” says Thornton.

Atoka City Industrial Development Authority, Oklahoma

Workforce programs stabilize the local economy and attract new business

In southeast Oklahoma, Atoka is centrally located two hours from Tulsa, Oklahoma City, Dallas and Fort Smith, Ark. Due to this strategic location, the Atoka City Industrial Development Authority has been successful in recruiting new industries to Atoka.

“These industries consistently search for locations that have a local trade or technical school,” says Carol Ervin, director of the Atoka City Industrial Development Authority.

Companies are drawn to Atoka’s Kiamichi Technology Center (KTC), which offers trade programs in automotive, carpentry, electrical, welding, construction technology and more. KTC will also custom-tailor a training program for industrial workers and in the past, has included specific equipment training and certifications for areas such as forklift safety and assembly-line training.

Local employers also tap into the OK Workforce apprenticeship program. It pairs new employees with seasoned workers, who mentor them for nine months. OK Workforce provides additional educational programs for the apprentice with incentives to the company to offset the cost. This program has proven successful regarding employee retention and lowering the high cost of employee turnover.

“A well-trained workforce helps stabilize our local economy, reduces turnover and outflow of workers,” says Ervin. “The workforce training programs reduce training costs for local businesses while encouraging investment in our local economy and improves the quality of life for our citizens.” T&ID